DURLON 8500

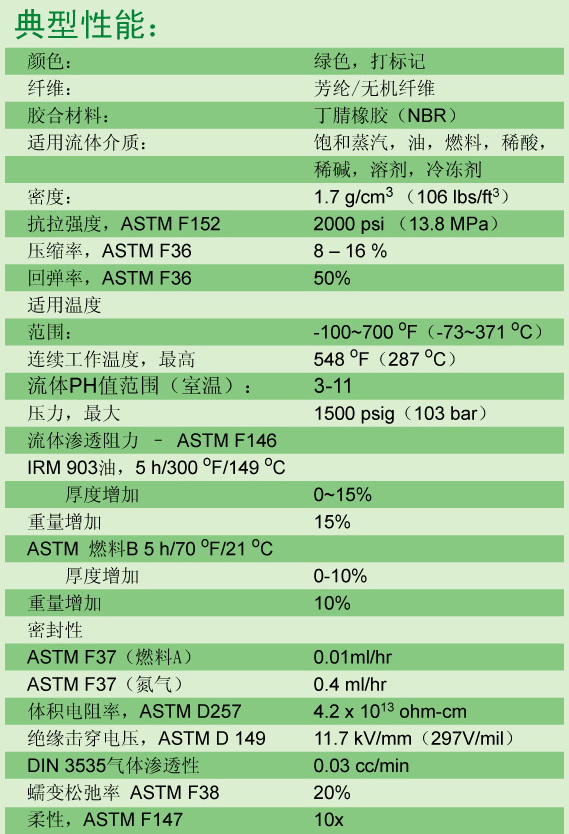

ASTM F104:F712120-A9B4E12K5L151M6

Asbestos free compression gasket material

Use:

DURLONR 8500 is the main gasket material for our company to shoulder the heavy responsibility. In the use of steam, gas, soybean processing and a new generation of refrigerant medium when the performance is very excellent. It is a high quality universal gasket material widely used in pulp, paper, food, beverage, medicine, chemical industry, refining, natural gas pipeline and general industry. DURLONR 8500 has excellent compression ratio and resilience, and has excellent sealing, flexibility and cutting performance.

Component:

DURLONR 8500 is made of high strength aramid fiber and inorganic fiber, and high quality of nitrile rubber (NBR) adhesive component. Fire resistance test: DURLONR 8500 successfully passed the improved version of API 607 fire test. When testing by direct flame scour part time is 30 minutes, within the first 15 minutes, flange temperature must reach 1200 degrees fahrenheit. The internal pressure must be kept at 30 psig during the test period. After the flame is extinguished, the test device is immediately sprayed with water and cooled rapidly. After 6 minutes of cooling, the leakage rate shall not be greater than 100 ml/min, so that the square is qualified. After the fire test, the leak test will be carried out.

Viscosity resistance:

All DURLON compression pad materials have done a great deal of work in developing adhesive release agents with superior adhesion resistance. All DURLON compression gasket materials were successfully through the military standard MIL-G-24696B 300 /48 hrs Naval Facilities anti adhesion test.

Note: the performance of the ASTM standard is measured according to the plate thickness 1/16 inches, but the ASTM F38 is measured according to the plate thickness 1/32 inches. These properties can only be used as a general reference and cannot be used as the basis for acceptance or rejection. The data shown in this table shall not be valid in the normal range of product performance and shall not be used in accordance with these data, technical regulations, or the use of these data independently as a basis for design.